From raw material to the finished product

Being a complete partner in our business means that we, with or without partners have the expertise and experience to develop a solution - product or service - that holds all the way to the final customer.

Through the years we have refined and improved our methods and our mechanical equipment to today be able to produce and process more complex parts and components.

Examples of end products is machine tubes, plungers, tubing, rotor shafts, pump shafts, piston rods, control rods generator shafts, axles, cylinders and shafts.

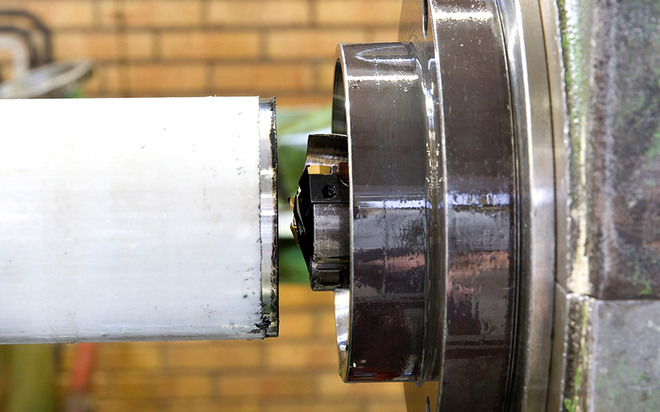

DEEP HOLE DRILLING

Knowledge related to experience, diameter versus depth. We can drill diameters from 2mm to 500mm diameter in lengths up to 13 meters. With the help of advanced systems, high professionalism and extensive experience, we can drill in most materials.

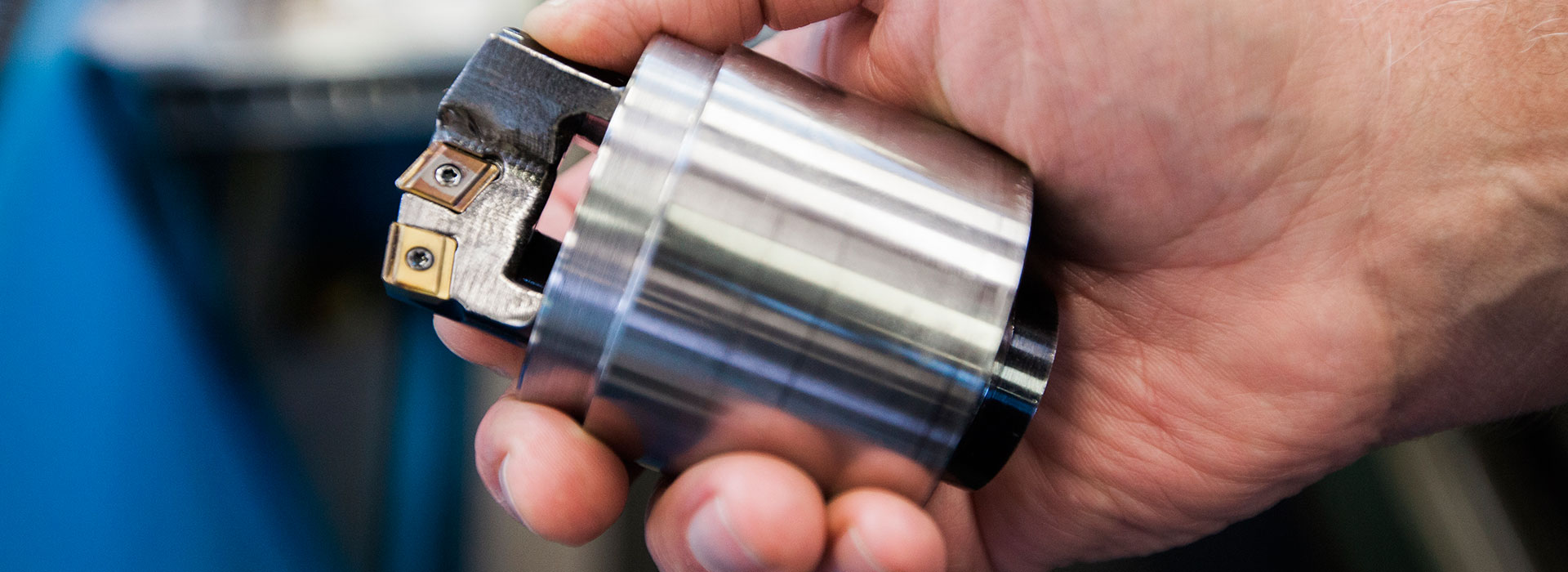

MECHANICAL PROCESSING

We are able to perform complicated, complex work that requires processing in several stages. In our CNC department we handle the most in turning and milling in lengths up to 14 meters. In our hone department we can manage to hone in lengths up to 8 meters with surface requirements down to Ra 0.05. In our straightening machine we are able to straighten shafts up to 500mm diameter.

OTHER SERVICES

Together with our partners, as most are geographically close to us, we can offer grinding, heat treatment, chrome plating and materials.

References

-

INDUSTRIAL HYDRAULICS

Cylinders

Piston rodsPHARMACEUTICAL INDUSTRI

Machinery

OFFSHORE INDUSTRY

Cylinders

Piston rods -

MINING INDUSTRY

Machine tubes

Pistons

Drill pipeSHIPBUILDING

Propeller shafts

-

ENERGY INDUSTRY

Long hole drilled rotor shafts and piston rods with internal sensors for wind power.

Pump shaft and control rods for the nuclear power industry.

Generator shafts for hydroelectric.